Capacity Reservation vs. Design Approval Timing Gap in Custom Stationery Procurement

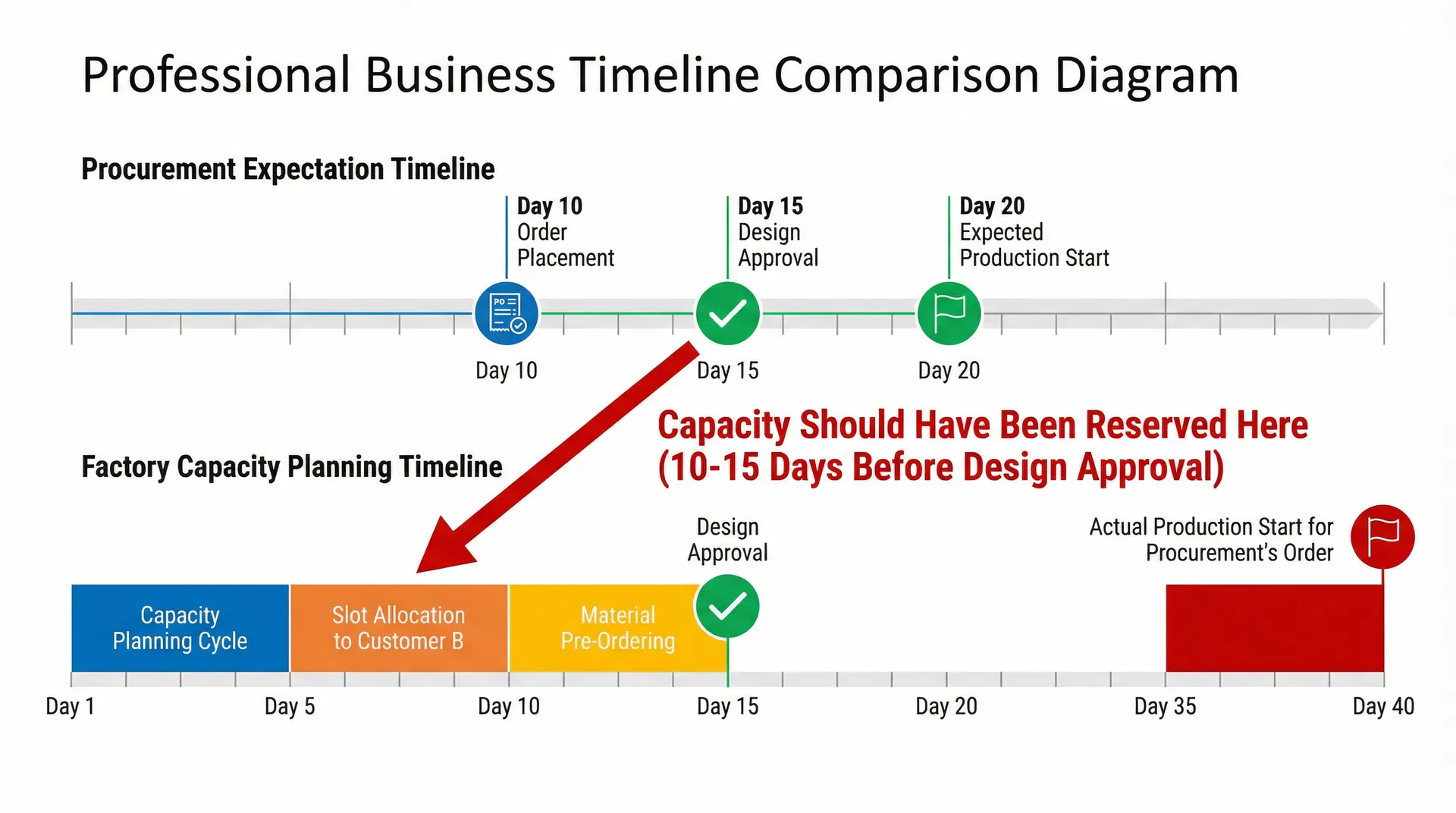

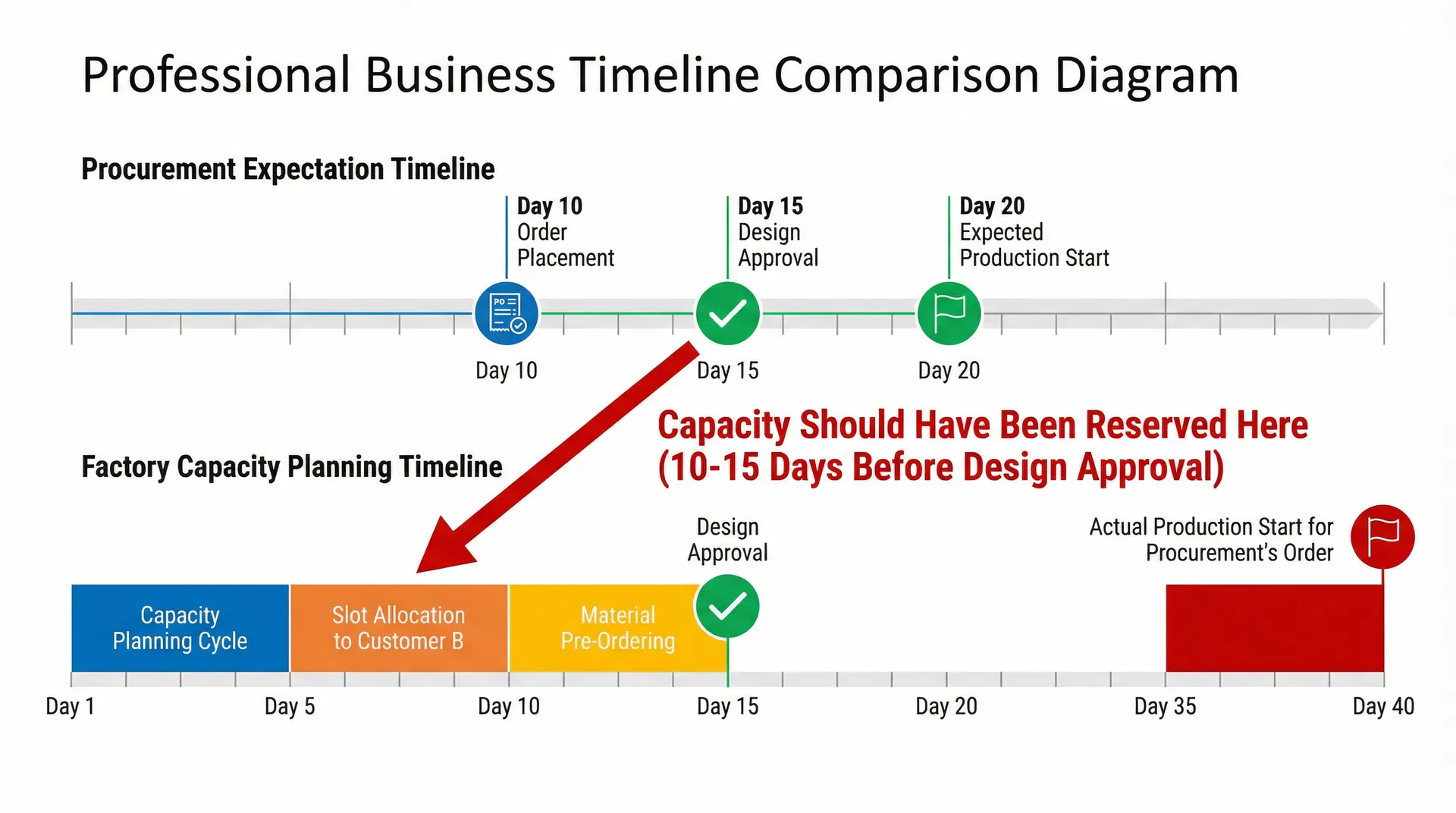

When procurement teams approve a custom leather notebook design on Day 15 and expect production to start on Day 20, they operate under the assumption that factory capacity is immediately available once design approval is secured. This assumption reflects a fundamental misunderstanding of how production slots are allocated in shared manufacturing environments. The capacity reservation lock does not occur after design approval—it occurs before it, often 10-15 days earlier, when the factory runs its capacity planning cycle and assigns production slots to orders with confirmed purchase orders and deposits.

In practice, this is often where customization process decisions start to be misjudged. Procurement teams treat design approval as the trigger point for production readiness, assuming that the factory will immediately allocate capacity to their order once the design is finalized. But factories operate on a different timeline. Capacity planning cycles run every 2-3 weeks, and production slots are allocated during these cycles based on confirmed commitments—not on pending design approvals. By the time procurement approves the design on Day 15, the production slot for Day 20 has already been allocated to another customer who reserved capacity on Day 5-10, when the factory last ran its capacity planning cycle.

The structural timing misalignment emerges from the way factories manage shared production lines. A leather goods manufacturer serving multiple corporate clients cannot afford to hold production capacity open for orders with pending design approvals. Production lines must maintain high utilization rates to remain economically viable, which means capacity is allocated to orders with confirmed commitments—purchase orders, deposits, and finalized specifications. When procurement places an order on Day 10 but delays design approval until Day 15, the factory's capacity planning cycle on Day 5 has already passed. The next cycle runs on Day 19-20, which means the earliest available production slot is Day 35-40, not Day 20.

Consider a scenario where a procurement team orders 500 custom leather notebooks with embossed logos and gilded edges. The order is placed on Day 10, but the design approval process—involving logo placement reviews, color matching, and edge finishing specifications—extends until Day 15. Procurement assumes that the 5-day gap between order placement and design approval is inconsequential, because the factory has not yet started production. But during this 5-day window, the factory has run its capacity planning cycle (Day 5), allocated the Day 20 production slot to Customer B (who confirmed their order with a deposit on Day 3), and pre-ordered materials for that slot (Day 10-15). When procurement's design approval arrives on Day 15, the Day 20 slot is no longer available. The next available slot is Day 35-40, which means the order will be delayed by 15-20 days relative to procurement's expectation.

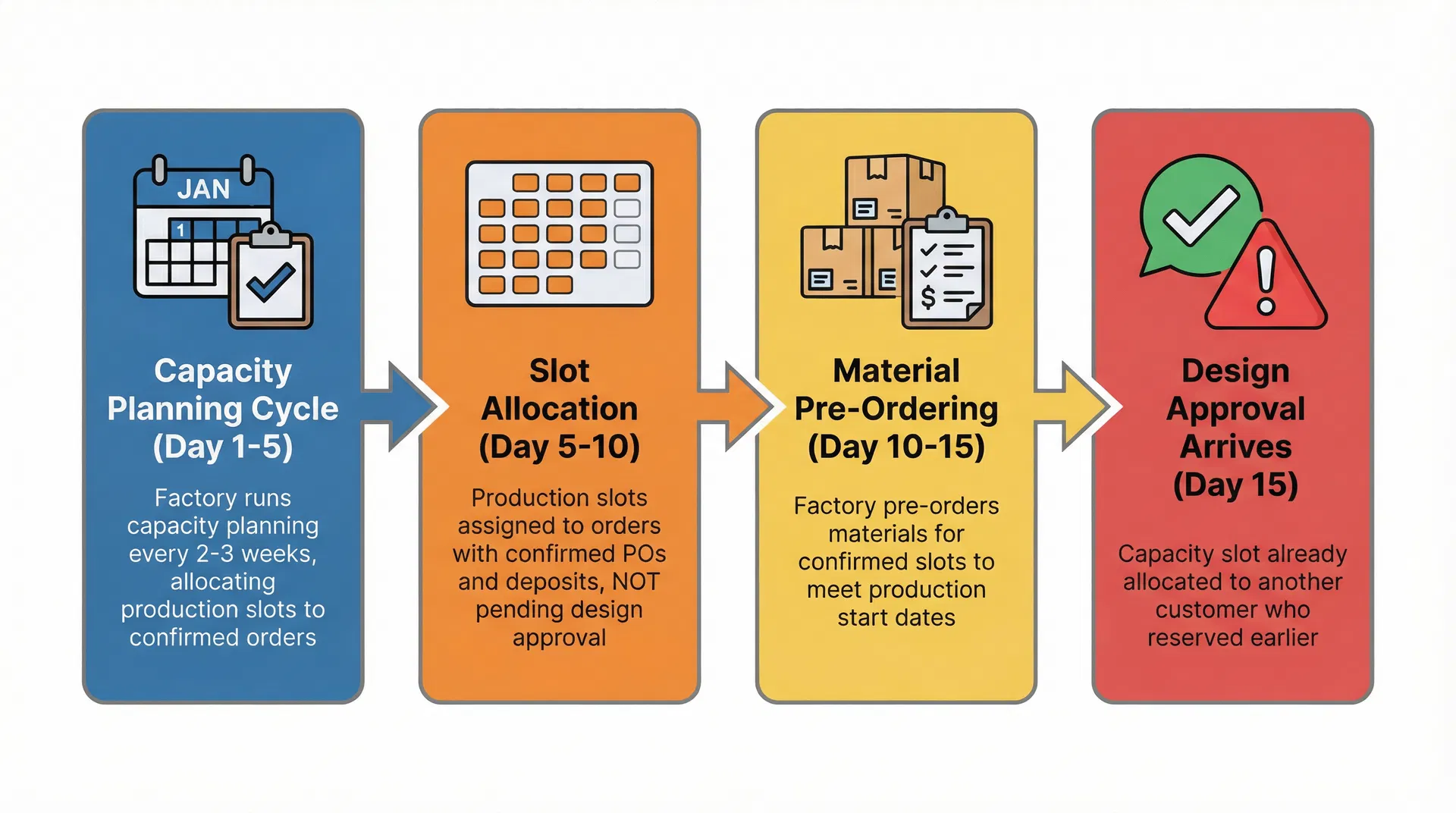

The capacity planning cycle operates on a fixed schedule because it synchronizes multiple operational functions. When the factory allocates a production slot on Day 5, it triggers a cascade of downstream activities: material procurement teams place orders for leather, paper, and metal components; production schedulers configure machine setups and operator assignments; quality control teams prepare inspection protocols for the specific customization requirements. These activities require 10-15 days of lead time before production can begin. If the factory were to allocate capacity on an ad-hoc basis—responding to design approvals as they arrive—it would lose the ability to coordinate these upstream activities, resulting in material shortages, machine downtime, and operator idle time. The capacity planning cycle exists to ensure that all resources are aligned before production begins, which is why it must run on a fixed schedule rather than reacting to individual order events.

Slot allocation prioritizes orders with confirmed commitments because factories face demand uncertainty. At any given time, a factory may have 10-15 orders in various stages of negotiation, design review, and approval. If the factory were to reserve capacity for all of these orders, it would hold 50-60% of its production capacity in reserve, waiting for design approvals that may or may not arrive. This would reduce capacity utilization to economically unsustainable levels. Instead, factories allocate capacity only to orders with confirmed purchase orders and deposits, which signal that the customer is committed to proceeding regardless of minor design adjustments. Orders with pending design approvals are queued for the next available capacity planning cycle, which runs 2-3 weeks later.

Material pre-ordering during Day 10-15 locks in the production slot allocation. Once the factory has placed orders for Italian leather, German paper stock, and brass gilding foil for Customer B's Day 20 slot, it cannot reallocate that slot to procurement's order without incurring material waste and supplier penalties. The leather supplier requires 10-day lead time and imposes a 20% restocking fee for cancelled orders. The paper mill requires 12-day lead time and does not accept cancellations within 7 days of delivery. These supplier constraints mean that once materials are ordered for a specific production slot, that slot is effectively locked to the customer for whom the materials were ordered. Even if procurement offers to pay a premium for expedited production, the factory cannot reallocate the Day 20 slot without absorbing significant material waste costs.

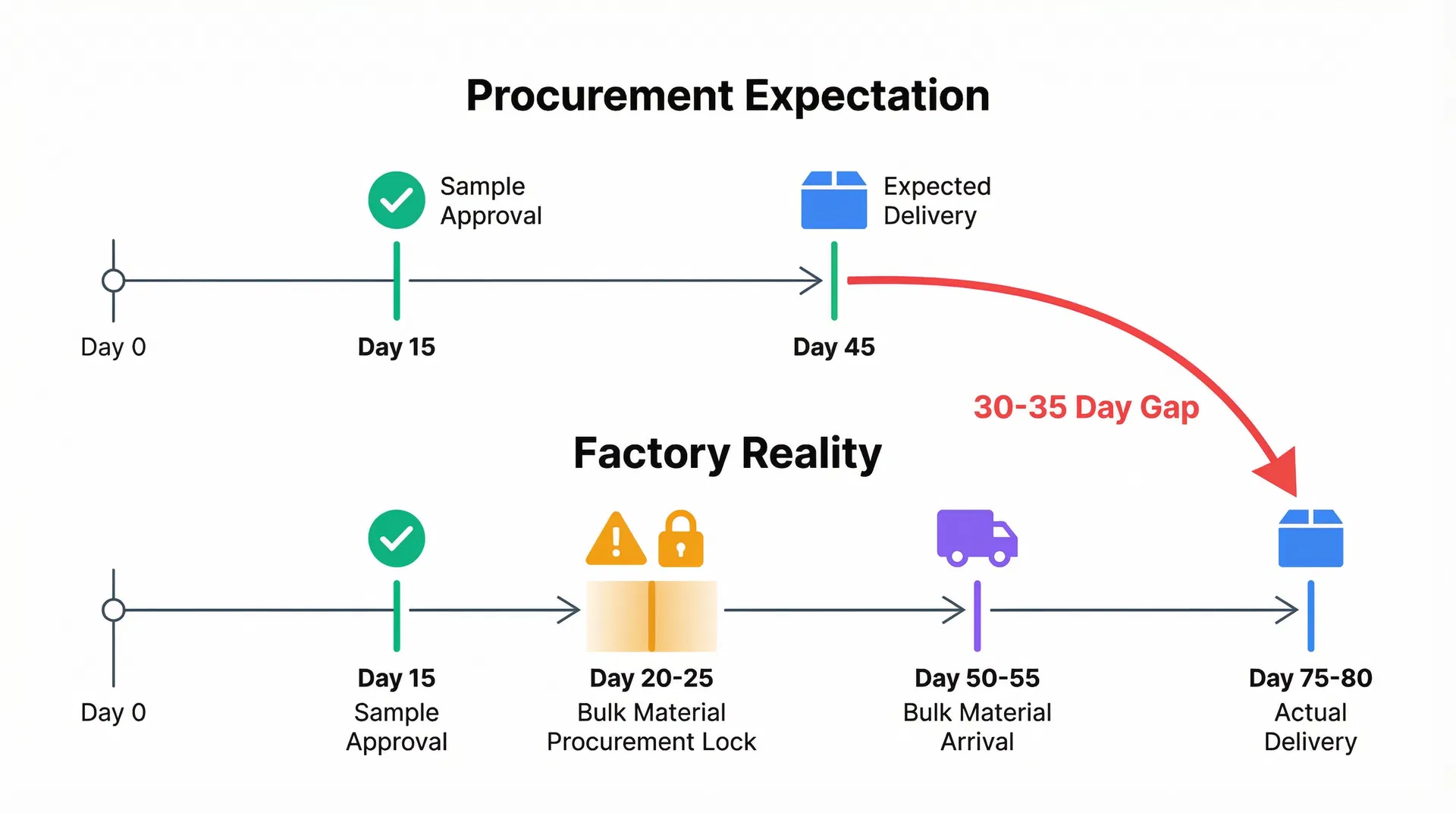

The timing gap manifests as an "invisible delay" because procurement measures lead time from design approval, while the factory measures it from capacity reservation. When procurement approves the design on Day 15 and receives delivery on Day 60, they calculate a 45-day lead time and compare it unfavorably to the factory's quoted 25-day production cycle. But the factory's 25-day cycle begins when production starts (Day 35), not when design is approved (Day 15). The 10-day gap between Day 15 and Day 35 represents the time required to queue the order for the next available capacity planning cycle and allocate a production slot. From the factory's perspective, the lead time is 25 days (Day 35 to Day 60), which matches the quoted cycle time. From procurement's perspective, the lead time is 45 days (Day 15 to Day 60), which appears to be a 20-day delay. This perceptual gap arises because the two parties use different reference points for measuring lead time.

The misalignment compounds when procurement teams attempt to expedite orders by offering premium payments. A procurement manager might contact the factory on Day 16 (one day after design approval) and offer a 15% premium for expedited production, expecting that the premium will secure immediate capacity allocation. But the factory cannot accept the premium without disrupting Customer B's order, which has already locked in the Day 20 slot through confirmed commitments and pre-ordered materials. The only way to accommodate procurement's expedited request would be to delay Customer B's order to Day 35-40, which would breach the factory's commitment to Customer B and damage the long-term relationship. Factories prioritize commitment reliability over short-term revenue opportunities, which means expedited requests are typically declined unless they can be accommodated within the next available capacity planning cycle.

The structural solution requires procurement teams to align their design approval timing with the factory's capacity planning cycle. If the factory runs capacity planning on Day 5, 19, and 33, procurement should aim to complete design approval by Day 3, 17, or 31—ensuring that the order is included in the next capacity planning cycle. This requires accelerating the design review process or initiating design discussions earlier in the procurement cycle. Some procurement teams address this by submitting provisional design approvals with the initial purchase order, reserving the right to make minor adjustments during the 10-15 day window before production begins. This approach secures capacity allocation while maintaining design flexibility, but it requires procurement to accept the risk that minor design changes may not be feasible if they conflict with pre-ordered materials or configured machine setups.

Capacity reservation deposits provide another mechanism for aligning timing. Some factories offer a capacity reservation option where customers can pay a 10-15% deposit to reserve a production slot before design approval is finalized. The deposit is non-refundable if the customer cancels the order, but it guarantees that the production slot will be available once design approval is secured. This shifts the timing risk from the factory to the customer: if design approval is delayed beyond the reserved slot, the customer must either accept the delay or forfeit the deposit. But for customers who are confident in their design approval timeline, the deposit option provides a way to secure capacity without waiting for the next capacity planning cycle.

The capacity reservation timing gap reveals a fundamental tension in customized stationery procurement: procurement teams optimize for design approval quality (taking time to finalize specifications), while factories optimize for capacity utilization (allocating slots to confirmed orders). Neither party is operating incorrectly—they are simply optimizing for different objectives within their respective operational constraints. The gap persists because design approval timing and capacity planning cycles operate on independent schedules, and neither party has visibility into the other's timeline. Procurement does not know when the factory's next capacity planning cycle will run, and the factory does not know when procurement's design approval will be finalized. This information asymmetry prevents both parties from coordinating their timelines, resulting in systematic delays that neither party can fully control.

The 10-15 day backward timing gap—from design approval (Day 15) to when capacity should have been reserved (Day 5-10)—represents the structural cost of operating in a shared manufacturing environment where multiple customers compete for the same production slots. Procurement teams who understand this timing structure can adjust their design approval processes to align with capacity planning cycles, reducing lead time by 15-20 days without requiring any changes to the factory's production schedule. Those who do not understand this structure will continue to experience "invisible delays" that appear to be factory inefficiencies but are actually timing misalignments between design approval events and capacity allocation cycles.